One big family

历史

Ecofrost 是匹卢维兹的一家新生企业,主要从事冷冻马铃薯产品,尤其是冷冻薯条业务。

Ecofrost 提供具有价格竞争优势的优质产品,满足最终客户的各种需求。为此,Ecofrost 承诺获得经济效益,以便保证未来的后续投资。

Ecofrost 最初由Vervaeke氏和Hoflack氏两个家族创立。

Pol 和 Dries Vervaeke 在鲜马铃薯交易中积累了三代人的经验,精通原材料方面的知识。他们也因此知道如何挑选正确的原材料,为承包的农户提供恰当支持。

Luc 和 Marc Hoflack 则在冷冻蔬菜方面拥有 25 年的经验。

现如今,这两个家族强强联合,创造了“马铃薯行业的新地标”。

公司成立于 2003 年,产品现销往全球 110 多个国家。我们的研发部门始终竭力满足国际客户的需求。

我们这家年轻的企业以诚信、灵活、团队合作、服务、品质和客户满意为指导原则。我们全体员工始终铭记这六条原则。

Already several times Ecofrost was named the fastest growing company by the Belgian business magazine Trends; For this they received in 2010 - 2011 and 2013 The famous trophy Trends Gazelles Award.

Ecofrost 提供具有价格竞争优势的优质产品,满足最终客户的各种需求。为此,Ecofrost 承诺获得经济效益,以便保证未来的后续投资。

Ecofrost 最初由Vervaeke氏和Hoflack氏两个家族创立。

Pol 和 Dries Vervaeke 在鲜马铃薯交易中积累了三代人的经验,精通原材料方面的知识。他们也因此知道如何挑选正确的原材料,为承包的农户提供恰当支持。

Luc 和 Marc Hoflack 则在冷冻蔬菜方面拥有 25 年的经验。

现如今,这两个家族强强联合,创造了“马铃薯行业的新地标”。

公司成立于 2003 年,产品现销往全球 110 多个国家。我们的研发部门始终竭力满足国际客户的需求。

我们这家年轻的企业以诚信、灵活、团队合作、服务、品质和客户满意为指导原则。我们全体员工始终铭记这六条原则。

Already several times Ecofrost was named the fastest growing company by the Belgian business magazine Trends; For this they received in 2010 - 2011 and 2013 The famous trophy Trends Gazelles Award.

目标消费群体

提供一体式代加工服务。代加工数量较低的可以冠以我们的品牌。

零售

我们的产品通过大型综合超市、超级市场、仓储式商场、商店、经销平台出售……

食品服务

Ecofrost 同时关注食品服务行业的客户,如餐厅、外卖店、酒店、学校、快餐店、医院……

食品行业

我们同时提供散装产品,因此可以用于现成食材或通过二次包装后重售。

Quick Service

We offer fries that stay crusty and warm for longer periods, ensuring they're ready to serve when the customer arrives.

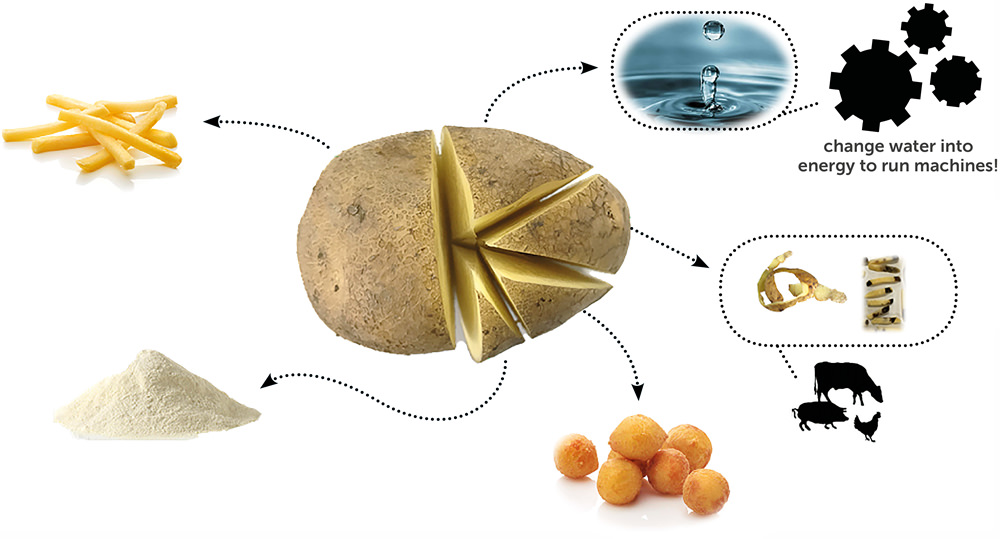

从马铃薯到薯条

从马铃薯到薯条

我们运用最新技术,提供口味多样、质地细腻和口感松脆的优质产品。

From potatoes to croquettes

我们重新利用最好的剩菜,即小薯条和土豆条,来制作土豆泥,这是我们专门生产炸丸子、炸土豆饼和其他特色菜的生产线的基本产品。

品质

成功的关键

客户满意度是我们的终极目标,而品质恰是实现这一目标的关键。因此,我们始终执行最为严格的卫生标准。此外,我们采用的扩展式 HACCP 体系全面运行,并被授予英国零售商协会/国际食品标准证书。

如果想了解更多薯条的烹饪方法,请点击以下链接:http://www.goodfries.eu

如果想了解更多薯条的烹饪方法,请点击以下链接:http://www.goodfries.eu

分销

打包后,产品会被存放在仓库的托盘上。我们的仓库中共有 60000 个托盘,库存空间充足。如果托盘达到适合的温度,就可以发给客户。

客户可以自己运输托盘,也可以请我们代为运输。我们随时为您提供最佳解决方案。

Ecofrost 的产品目前出口 150 多个国家,涵盖四大洲。

客户可以自己运输托盘,也可以请我们代为运输。我们随时为您提供最佳解决方案。

Ecofrost 的产品目前出口 150 多个国家,涵盖四大洲。

环保

Ecofrost 刚刚进行了绿色投资,这不仅对环境产生了重大积极影响,而且还将减少气味和冷凝(烟羽)排放。

Ecofrost 还拥有高科技水净化系统和沼气厂。

此外,该公司还拥有“精益和绿色”标签。要了解更多相关信息,您可以在页面底部找到更多信息。

Ecofrost 还拥有高科技水净化系统和沼气厂。

此外,该公司还拥有“精益和绿色”标签。要了解更多相关信息,您可以在页面底部找到更多信息。

电

计划中:现场生产和消费的电力、绿色能源减少 5%

浪费

现场处理 50,000 吨马铃薯废料

CO²

道路上行驶的 40 吨卡车减少 800 辆 - 二氧化碳排放量减少 130,000 吨

绿色热能

12.5%绿热

水

回收总用水量的 40%

肥料

每年2000吨土壤肥料

Lean & Green

Since the creation of the company in 2003, the rational use of energy has always been at the center of our concerns, at every phase of the design of our various production lines.

In 2014, in order to improve our performance in terms of energy consumption, the company entered into the branch agreement program concluded between the Walloon region and the federation of the food industry FEVIA.

Since this reference year, CO2 emissions on the process part have decreased by 13%.

The main reduction measures were:

- Heat recovery from the production process

- Reduction of water consumption

- Heat insulation

- Control of purges on boilers, bleachers and cooling towers

- Installation of photovoltaic panels

The "Lean and Green" program is an opportunity for Ecofrost to continue and challenge its efforts to reduce CO2 emissions in areas not yet explored such as supply, shipping and storage.

In summary, our so-called transport actions will allow us to reduce our emissions by 18.99% and those classified in logistics by 9.03% for a planned total of 28.02%.

This gain is well above the 20% threshold assigned to the Lean & Green objective.

Reduced to the reference unit, in Tons, our objective would be to go from 60.48 Kg CO2 / T to 43.53 Kg CO2 / T

In relation to the impact on the logistics chain, our actions generate a relative gain of:

- 8.29% on incoming products

- 9.23% on finished products

- 10.5% on products invoiced or shipped in this case

This distribution shows a balanced effort between the three main stages of the logistics process retained in the Lean & Green program.

In the food sector, we are one of the first producers to obtain the certificate and of course, are very proud of it. A word of thanks to the colleagues from Logistics in Wallonia who guided us very well in this!