One big family

Istorie

Ecofrost Inc, este o companie Belgiana tanara localizata in Peruwelz. Suntem specializati in cartofi congelati, in special chips-uri congelate.

Ecofrost ofera produse de calitate la preturi competitive, luand in considerare schimbarea continua a modelelor cererii de consum ale clientilor finali. In acest scop, Ecofrost s-a angajat sa depuna eforturi pentru a fi profitabil, astfel ca investitia in viitor poate fi garantata.

Ecofrost Inc, a fost fondata de 2 familii, familia Vervaeke si familia Hoflack. Poland Dries Vervaeke, care a venit dintr-o familie de trei generatii care se ocupa cu comertul cu cartofi proaspeti, a oferit cunostintele despre materia prima.Cu aceasta experienta, ei stiu sa aleaga materia prima potrivita si sa sprijine agricultorii lor sub contract in mod corespunzator.

Luc si Mark Hoflack au 45 de ani de experienta in legume congelate. Impreuna ei ofera o sinergie perfecta, care creaza " a noua semnatura in lumea cartofilor".

Inca de la infiintarea companiei in 2003, Ecofrost Inc. livreaza produsele in peste 150 tari din intreaga lume. Departamentul nostru R&D este intotdeauna gata de a incerca si de a indeplini nevoile clientelei internationale.

Principiile companiei noastre tinere sunt increderea, flexibilitatea, spiritul de echipa, servicii, calitatea si satisfacerea clientului. Sase puncte pe care angajatii nostrii le au in minte.

Ecofrost ofera produse de calitate la preturi competitive, luand in considerare schimbarea continua a modelelor cererii de consum ale clientilor finali. In acest scop, Ecofrost s-a angajat sa depuna eforturi pentru a fi profitabil, astfel ca investitia in viitor poate fi garantata.

Ecofrost Inc, a fost fondata de 2 familii, familia Vervaeke si familia Hoflack. Poland Dries Vervaeke, care a venit dintr-o familie de trei generatii care se ocupa cu comertul cu cartofi proaspeti, a oferit cunostintele despre materia prima.Cu aceasta experienta, ei stiu sa aleaga materia prima potrivita si sa sprijine agricultorii lor sub contract in mod corespunzator.

Luc si Mark Hoflack au 45 de ani de experienta in legume congelate. Impreuna ei ofera o sinergie perfecta, care creaza " a noua semnatura in lumea cartofilor".

Inca de la infiintarea companiei in 2003, Ecofrost Inc. livreaza produsele in peste 150 tari din intreaga lume. Departamentul nostru R&D este intotdeauna gata de a incerca si de a indeplini nevoile clientelei internationale.

Principiile companiei noastre tinere sunt increderea, flexibilitatea, spiritul de echipa, servicii, calitatea si satisfacerea clientului. Sase puncte pe care angajatii nostrii le au in minte.

Cui ne adresam

Intreaga sortimentatie de produse poate fi oferita in marca proprie. Pentru volume mici putem oferi brand-ul nostru.

Retail

Produsele noastre sunt vandute prin intermediul retailarilor in hypermarketuri, supermarketuri, Cash& carries, magazine, platforme de distributie....

Food service

De asemenea Ecofrost se adreseaza clientilor din zona de food serivce, precum restaurante, hoteluri, mancare pentru acasa, fast food-uri, spitale....

Procesatori

Oferim produsele noastre vrac, acestea pot fi folosite la prepararea mancarurilor sau reambalate pentru revanzare.

Quick Service

Oferim cartofi prăjiți care rămân crocanți și calzi pentru perioade mai lungi de timp, asigurându-ne că sunt gata de servire atunci când sosește clientul.

Productia

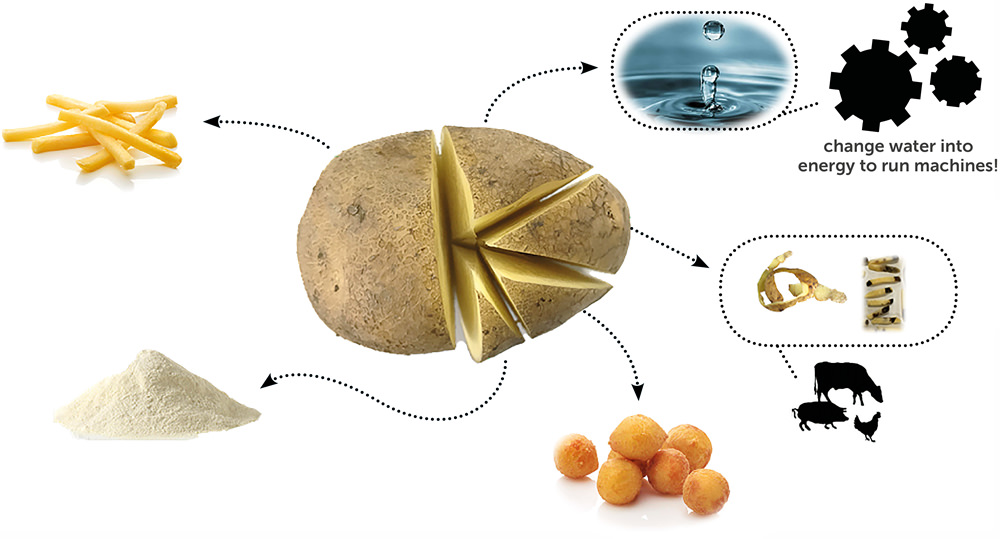

De la cartof la cartofi prajiti

Utilizand cele mai noi tehnologii, sutem oferii produse de cea mai buna calitate- un produs cu un gust bogat, textura uniforma si senzatie crocanta.

De la cartofi la crochete

Reutilizăm resturile noastre de top, și anume cartofii prăjiți mici și feliile de cartofi pentru a face piure de cartofi, care sunt produsul de bază al liniei noastre specializate pentru a produce crochete, noisettes și alte specialități.

Calitate

Cheia sucesului

Satisfacerea clientului este scopul nostru principal si calitatea este cheia pentru a realiza acest lucru. Prin urmare, sunt puse in aplicare cele mai stricte standarde de igiena. Mai mult decat atat, un sistem extins HACCP este pe deplin operativ si premiat cu un certificat BRC/IFS.

Vreti sa stiti mai mult despre cum sa prajiti cartofii, atunci va sugeram sa vizitati unrmatorul link http://www.goodfries.eu

Vreti sa stiti mai mult despre cum sa prajiti cartofii, atunci va sugeram sa vizitati unrmatorul link http://www.goodfries.eu

Distributia

Dupa ambalare, produsele sunt depozitate pe paleti in depozitul nostru. Aici avem o capacitate totala de aproximativ 60,000 paleti. In situatia in care acesti paleti au ajuns la temperatura corecta acestia pot pleca catre client.r.

Dupa cum preferati, puteti sa ridici paletii sau putem sa punem la dispozitie transport pentru D-voastra. Suntem gata sa va ajutam sa gasim cea mai buna solutie.

In prezent Ecofrost exporta in peste 150 tari diferite, raspandite pe cele 4 continente.

Dupa cum preferati, puteti sa ridici paletii sau putem sa punem la dispozitie transport pentru D-voastra. Suntem gata sa va ajutam sa gasim cea mai buna solutie.

In prezent Ecofrost exporta in peste 150 tari diferite, raspandite pe cele 4 continente.

Mediu inconjurator

Ecofrost tocmai a făcut investiții ecologice, care nu numai că au un impact pozitiv major asupra mediului, dar vor reduce și mirosurile și emisiile de condens (pene de fum).

Ecofrost are, de asemenea, un sistem de purificare a apei de înaltă tehnologie și o instalație de biogaz.

În plus, compania deține eticheta „Lean and Green”. Pentru a afla mai multe despre acest subiect, veți găsi mai multe informații în partea de jos a paginii.

Ecofrost are, de asemenea, un sistem de purificare a apei de înaltă tehnologie și o instalație de biogaz.

În plus, compania deține eticheta „Lean and Green”. Pentru a afla mai multe despre acest subiect, veți găsi mai multe informații în partea de jos a paginii.

Electricitate

În curs de dezvoltare: -5% din electricitatea produsă și consumată la fața locului, energie verde

Deşeuri

50.000 de tone de deșeuri de cartofi procesate la fața locului

CO²

Cu 800 de camioane de 40 de tone mai puține pe drumuri - cu 130.000 de tone mai puține de emisii de CO²

Căldură Verde

12,5% căldură verde

Apă

Recuperarea a 40% din necesarul total de apă

Fertilizare

2.000 de tone de fertilizare a solului pe an

Lean & Green

Since the creation of the company in 2003, the rational use of energy has always been at the center of our concerns, at every phase of the design of our various production lines.

In 2014, in order to improve our performance in terms of energy consumption, the company entered into the branch agreement program concluded between the Walloon region and the federation of the food industry FEVIA.

Since this reference year, CO2 emissions on the process part have decreased by 13%.

The main reduction measures were:

- Heat recovery from the production process

- Reduction of water consumption

- Heat insulation

- Control of purges on boilers, bleachers and cooling towers

- Installation of photovoltaic panels

The "Lean and Green" program is an opportunity for Ecofrost to continue and challenge its efforts to reduce CO2 emissions in areas not yet explored such as supply, shipping and storage.

In summary, our so-called transport actions will allow us to reduce our emissions by 18.99% and those classified in logistics by 9.03% for a planned total of 28.02%.

This gain is well above the 20% threshold assigned to the Lean & Green objective.

Reduced to the reference unit, in Tons, our objective would be to go from 60.48 Kg CO2 / T to 43.53 Kg CO2 / T

In relation to the impact on the logistics chain, our actions generate a relative gain of:

- 8.29% on incoming products

- 9.23% on finished products

- 10.5% on products invoiced or shipped in this case

This distribution shows a balanced effort between the three main stages of the logistics process retained in the Lean & Green program.

In the food sector, we are one of the first producers to obtain the certificate and of course, are very proud of it. A word of thanks to the colleagues from Logistics in Wallonia who guided us very well in this!